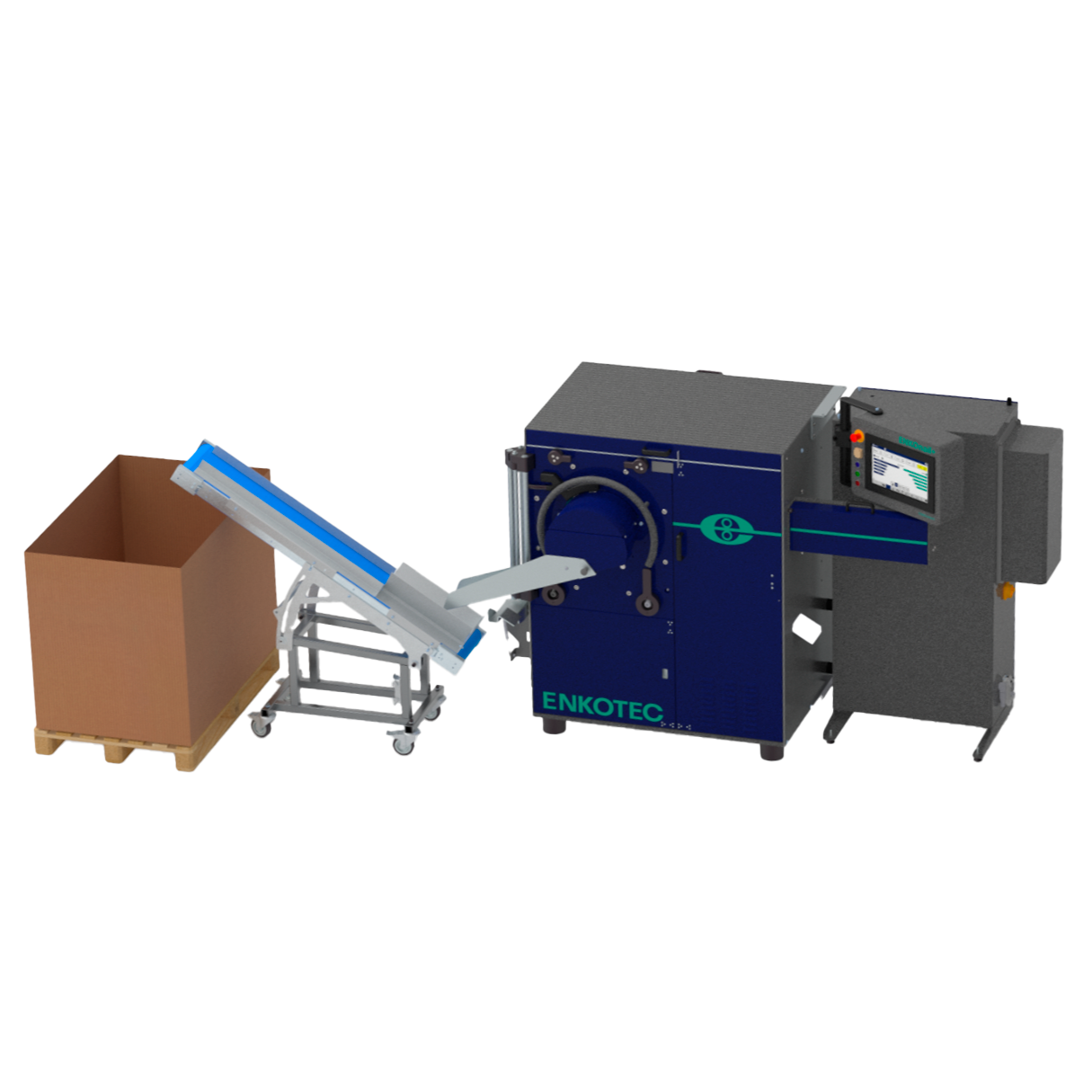

ENKOveyor: Belt Conveyor For Transporting Nails

Our belt conveyor is used for the transportation of all nail types from a nail machine or thread roller into a box or bin.

We have two versions of this conveyor belt: a smart version or and a standalone version. Both belts are designed to be easily manoeuvrable, flexible and highly adjustable for customer specific nail boxes or bins.

The ENKOveyor: Standalone Belt, type CB03, is a standalone conveyor belt used for the transportation of nails from a nail machine or thread roller into a box or nail bin. This version is compatible with a wide range of machinery and has only basic transportation functionality.

The ENKOveyor: Smart Belt, Type CB02, is able to integrate with the ENKOsmart platform, unlocking more capabilities.

Datasheets:

Conveyor Speed:

20kg/Minute

Weight:

70 kg/7172 lbs

Buffer Capacity:

Smart Belt CB02: Max 3,500 nails

Standalone Belt CB03: No Buffer Capacity

- Buffer capability

- Sensor-controlled nail bin filling

- Automatic start/stop function

- Compatible with NX03 & TR01*

- No accumulation - increased OEE

- Very flexible nail transportation solution

- Easily manoeuvrable

- Highly adjustable

- Standalone solution, no in-line setup required

- Compatible with older machine models

- Simple and cost-effective solution

- No accumulation - increased OEE

- Very flexible nail transportation solution

- Easily manoeuvrable

- Highly adjustable

Smart Conveyor Designed For In-Line Production

The ENKOveyor: Smart Belt is a smart conveyor belt used for the transportation of nails from an ENKOnail+ or ENKOroll into a box or nail bin. With this belt, all the operator needs to worry about is changing over a box or bin when it's full - and the rest of the in-line set up will take care of itself.*

This belt has been specifically designed to run in an ENKOline set up. When paired with other ENKOsmart machinery, this solution enables the ENKOlines automatic start/stop features, reducing the labour needed to run an in-line setup and increasing Overall Equipment Effectiveness (OEE).

*Requires in-line functionality