ENKOpayoff: Designed For Optimum Wire Utilisation

Our wire payoff is specially designed to supply wire to ENKOnail machines, ensuring optimum wire rod utilisation.

The ENKOpayoff gets its name from the fact that it quite literally "pays off" to have one. Designed specifically to feed our high-speed nail manufacturing machines, the ENKOpayoff ensures that production runs smoothly and efficiently.

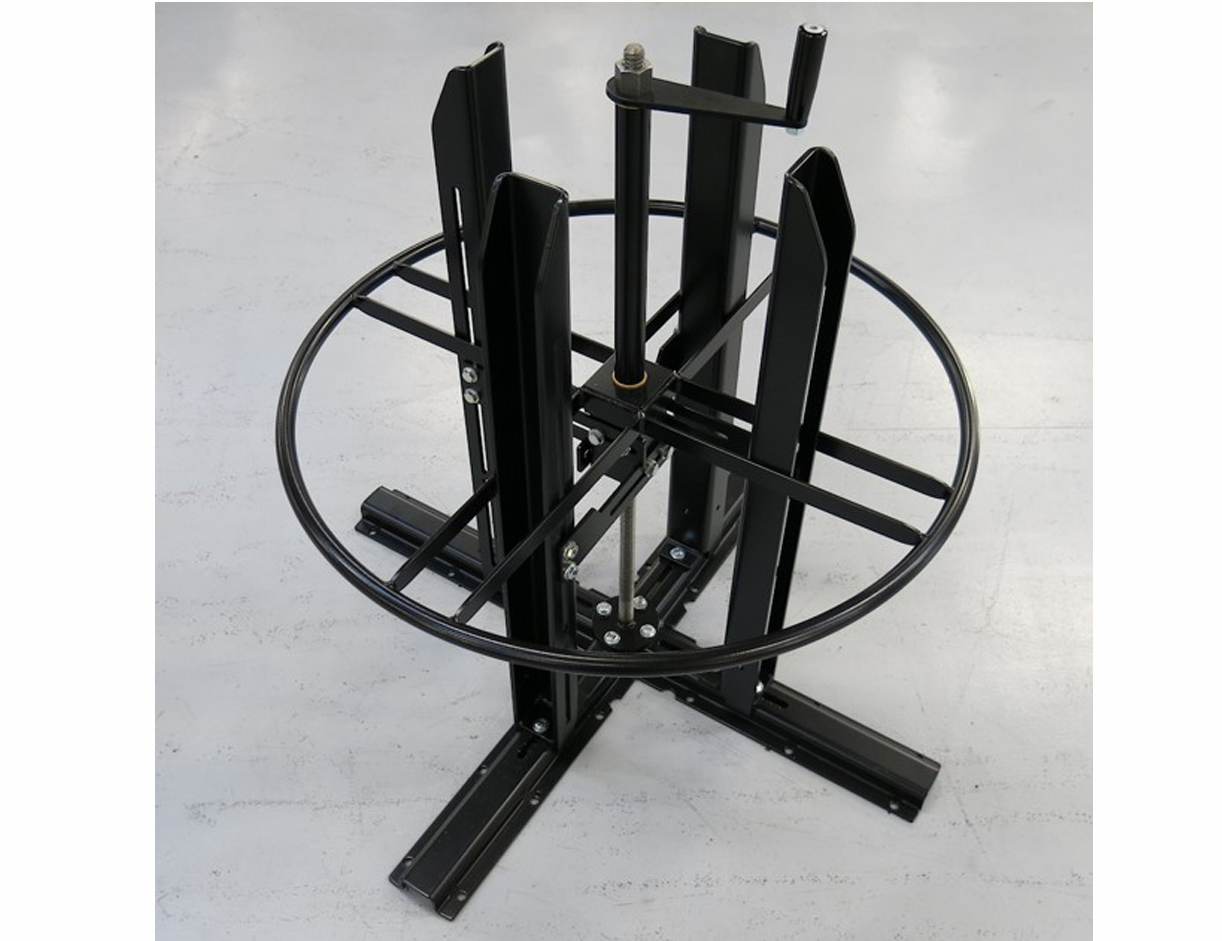

The turntable is driven through a helical bevel geared motor and the speed is adjusted by a speed control arm via a non-contact sensor. An electro-magnetic spring-loaded brake stops the turntable instantly and safely when the ENKOpayoff is switched off.

Datasheets:

- PD01 with integrated controls

- PD02 with external control box

- Speed control arm

- Electro-magnetic spring-loaded brake

- Ensures a steady feed of wire

- Compact

- Compatible with all ENKOTEC nail making machines

Weight of Coil:

Max 2,000 kg / 4,400 lbs

Outside Diameter of Coil:

Max 1,000 mm / 39”

Inside Diameter of Coil:

380 - 620mm / 15 - 23”

Models For All Nail Machine Types

The ENKOpayoff type PD01 features a PLC-controlled touch screen, which is integrated into our ENKOnail+ machine series and in the ENKOnail MI01 nail machine. The ENKOpayoff type PD02 is for use with older models of nail machinery and comes with external controls.

The payoffs can be supplied with an ENKOTEC wire coil stand designed for easy handling and fixation of strapped wire coils without drums. The stand, which covers a wide range of coil diameters and heights, can be mounted on an existing payoff turntable and is easily adjusted to the specific wire coil dimensions.

Due to its high operating speed, we recommend using either a basic fence or an ENKOfence with the ENKOpayoff, to ensure maximum user safety.