ENKOllator: Plastic Strip Nail Collating Machine

The ENKOllator: Plastic Strip runs at a speed of up to 2,000 nails per minute and is the perfect match for our nail machines.

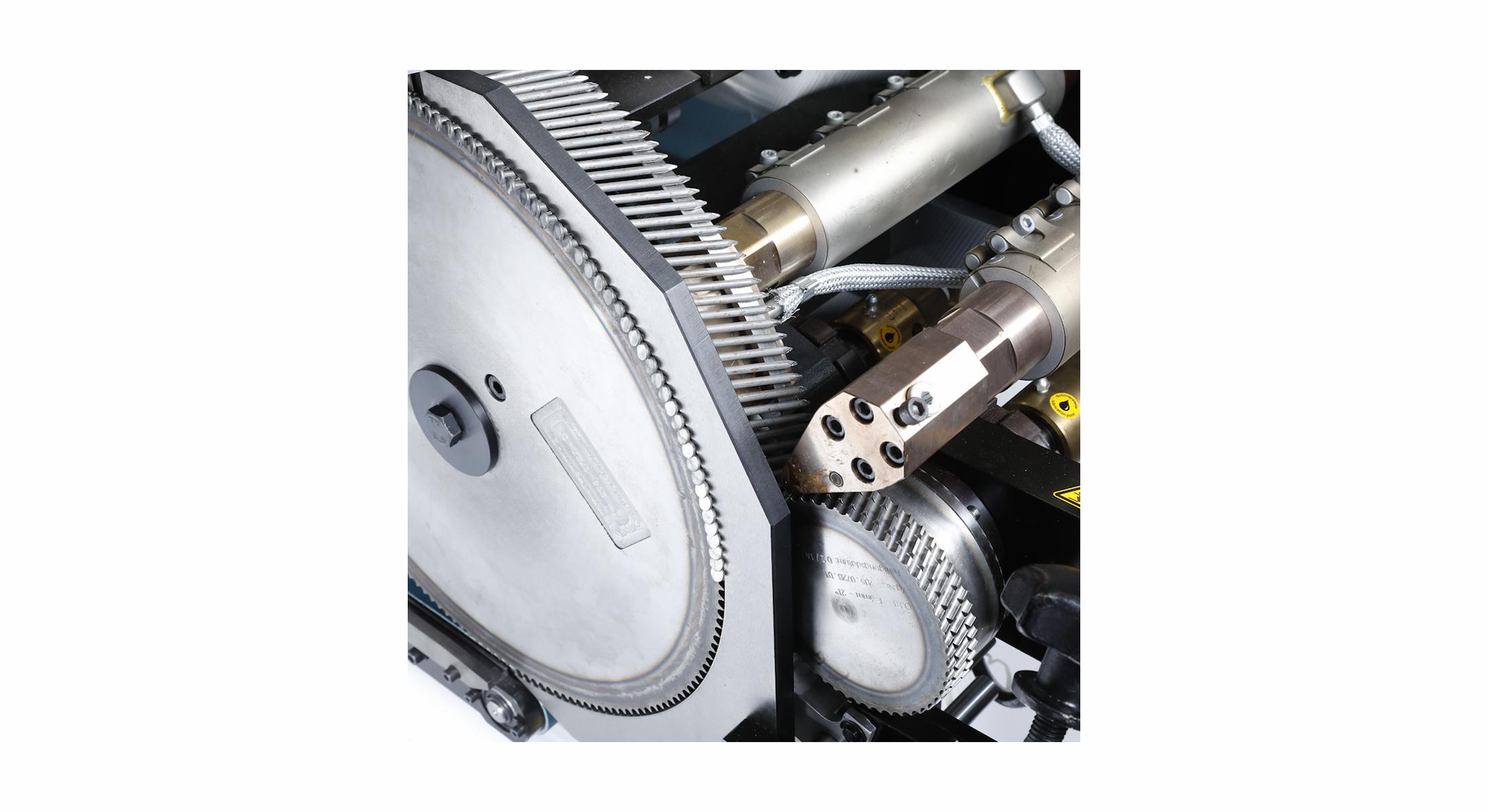

Our plastic strip collator, type CPS01, is designed for making plastic collated strip nails, using servo drive technology in all processes. The collator has been designed to be compatible in an in-line setup or as a standalone machine.

The ENKOllator: Plastic Strip can collate the following types of nails, with a smooth, ring or screw shank:

- Bright

- Electro-Galvanized

- Hot Dipped Galvanized

- Stainless-steel nails

Datasheet:

- Extremely high efficiency

- Minimum changeover times

- Closed cooling circuit for plastic moulding process

- ENKOTEC designed and built feeder bowl

- Operator-friendly construction built on experience

- Extremely high tool lifetime

Nail Diameter:

Ø 2.5 - 4.0 mm / 1 - 0.157”

Nail Length:

45 - 100 mm / 1.77- 3.9”

Nails Per Strip:

20 - 40

Production Capacity:

Up to 2,000 nails/minute

Highly Efficient Nail Collation with Servo Drive Technology

The nails are carried by an ENKOfeed to a pair of guide tracks, put into the required position and transported to two plastic extruding heads at a speed of up to 2,000 nails per minute.

Two water cooled pressure wheels shape and cool the plastic into a strip. After the plastic forming process, the endless strip is cut to the required length and thereafter coated by a dosing pump.

The strip handling unit, PSC02, takes over the nail strips from the CPS01 and stores the coated strips in a rotating wheel for a sufficient drying period. Afterwards, the strips are stacked in up to 10-strip-stacks onto a conveyor belt, where the stacks are picked off and packed into cartons by the operator.